Wireline | Performance in Perforating

We're wired differently.

Why NexTier Wireline?

We deliver something you might not expect from the premier wireline plug-and-perf company in the US: exceptional flexibility and personal attention to detail.

[Hover images to learn more]

- Exceptional scope and scale in US land plays

- Unmatched customer service and wireline expertise

- Industry’s longest wireline services history

- Vast cache of historical data for every major shale play

- Superior digital connectivity

- 24/7 remote support

- Improved wellsite synergies and efficiencies

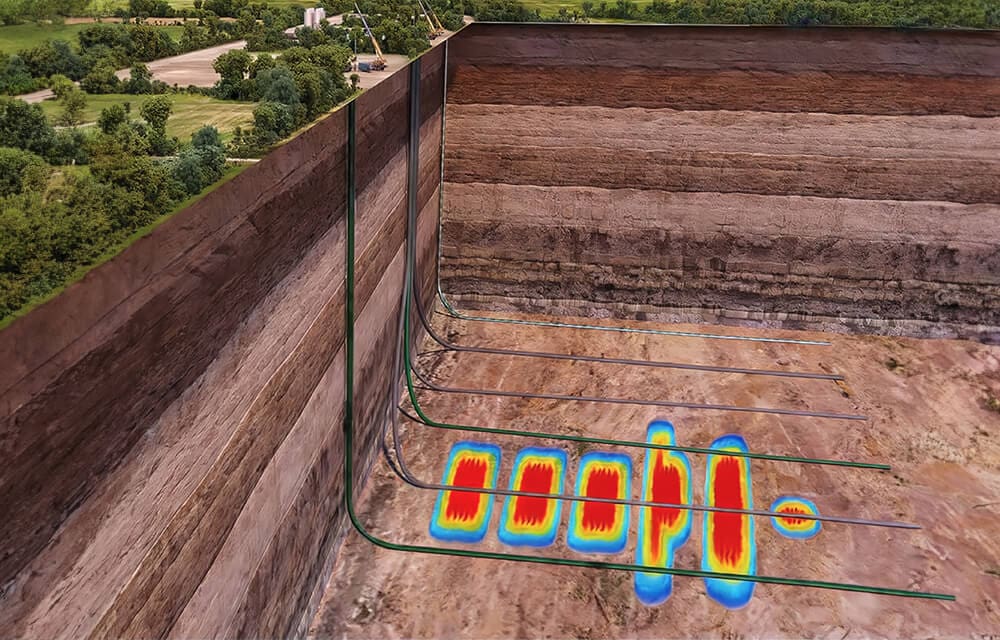

True leader in wireline plug and perf

- Exceptional scope and scale in US land plays

- Unmatched customer service and wireline expertise

Legacy wireline operations

since 2005

- Industry’s longest wireline services history

- Vast cache of historical data for every major shale play

Integrated completions value

- Superior digital connectivity

- 24/7 remote support

- Improved wellsite synergies and efficiencies

Goals and strategies designed around yours.

Emerald™ Fleet Technology

Unleash Power and Performance: Emerald™ Fleet Technology

Reach the pinnacle of oilfield innovation with latest-generation equipment, alternative fuel capabilities, and digital integration.

NexTier integration. Unbeatable advantages.

- Average of 20% more frac stages completed per day*

- Fewer personnel required on-site

- Seamless data sharing, enabled by our NexHub™ Digital Center

*Compared to NexTier frac sites working with third-party wireline services, over the 18-month period ending 06/30/22.

Our strongest oilfield asset: Exceptional people.

Poised for performance: Top-tier field equipment.

- Digitized winch run by software for programmable safeguards and automation

- Rotating Drum Base +/- 10 degrees for quick and easy spotting

- Integrated auto-rate pumpdown controls

- Powered by any in-field electric source

- Backup diesel power

- Less maintenance – no regen required

- Automatically achieves target rate using proprietary MDT controls

- Reduces personnel on location

- Enables identical runs with regards to pump operation

- Reduces water usage by an average of 5.6%

- Elimination of radio communication speeds up reaction time by 2.3x

- Fast, remote connections

- Keeps personnel out of high-pressure zone

- Optional NexTier-exclusive rotary ball dispenser (RBD)

- Makes ball drops up to 150 ft away from the wellhead

- No grease-injection system required

- Eliminates risk of grease contamination

- Reduces environmental impact

- Polymer-coated wire

- Reduces friction

- Prevents bird-caging and related downtime

- Enables up to 60 runs between re-heads

Let's Get Started

Better completions.

Every step of the way.

If you’re ready to boost performance in your wireline operations – or in any aspect of your completion design – we’re ready to help!

Driven By Our People

Careers at NexTier

Whether you’re an entry-level applicant or an experienced pro in the energy industry, we offer the training and cutting-edge technologies to help you create the future you want.