EMERALD™ FLEET TECHNOLOGY

The Next Generation of Power and Performance

The Next Generation of Power and Performance

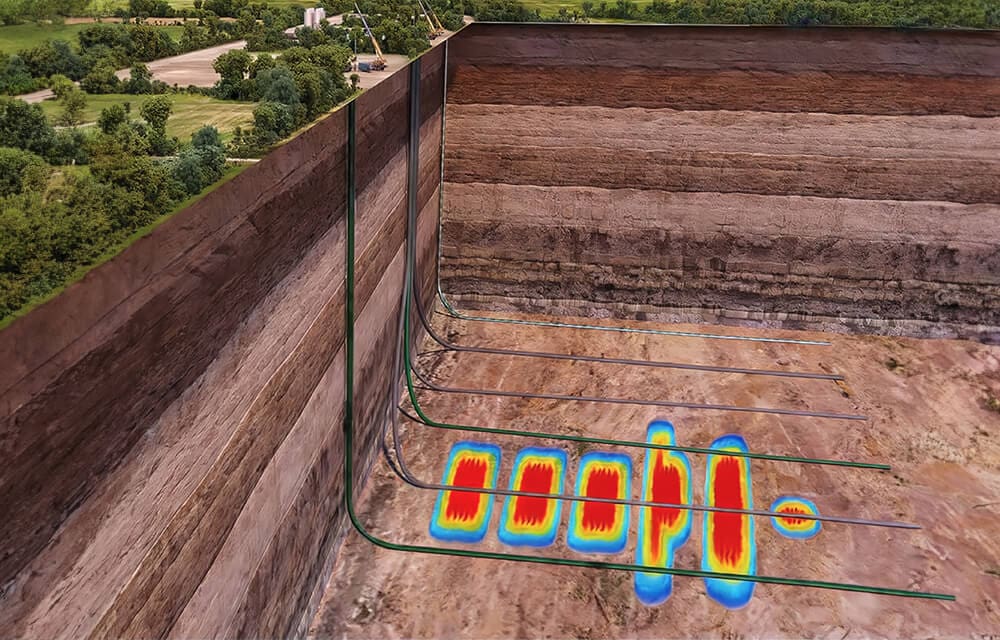

Emerald™ Fleet Technologies represent the pinnacle of modern oilfield innovation. With latest-generation equipment, alternative fuel capabilities, and digital integration, Emerald™ delivers unmatched efficiency, sustainability, and performance.

Emerald™ Electric Drive Frac Pump

Power and Flexibility, Electrified

Delivering up to 5,000 BHP per trailer. Designed for durability and flexibility, it ensures long service life, reduced emissions, and efficient operations.

- 5,000 BHP with continuous-duty-rated drives for full-range performance.

- Compact and Reliable: Maximum HHP per trailer with infinitely variable motors for superior rate balancing.

- Flexible Power: Compatible with Highline, field, or mobile generator power.

- Quick Deployment: Integrated controls enable fast rig-up with minimal cables.

- Sustainable: Lowest emissions possible when paired with grid power.

Emerald™ Gas Drive Recip Frac Pump

Harnessing the Power of Natural Gas

Advanced, 100% natural-gas power that augments diesel fleets—delivering higher mechanical efficiency, lower fuel cost, and a smaller pad footprint for modern frac operations.

- Lower operating cost: Up to $1.8MM estimated annual fuel savings per pump vs diesel (assumptions available).

- Capacity without the sprawl: On pad-constrained sites, one gas drive pump can often replace 2.5 diesel pumps

- Fuel flexibility: 100% natural-gas capable with field-gas/CNG pathways; methane number >70 recommended for max horsepower.

- Efficiency you can feel: Engineered for 10–15% greater efficiency vs other next-gen fracturing technologies, turning more fuel into work.

- Power & pressure: 3,600 BHP, up to 13.7 bpm (5″ plungers), up to 15,000 psi (4.5″ plungers).

- Digital by default: EOS™-ready controls and workflows for consistent, data-backed stage performance.

Emerald™ Electric Blender

Precision Placed Treatments

Designed to extend component life, improve efficiency, and ensure safety. With its automation-enabled, operator-free design, it eliminates red-zone exposure while delivering exceptional performance for high-demand simul-frac operations.

- High Capacity: Handles up to 200 BPM for split-stream applications.

- Zero Hydraulics: Fully electric system powered by a 480-volt configuration for greater reliability.

- Simul-Frac Ready: Tailor-made for high-demand simul-frac operations with multiple sand delivery system compatibility.

- Precision Control: MDT control system ensures targeted discharge pressure and consistent supply pressure to frac pumps.

- Unmanned Operations: Automation-enabled design supports remote and operator-free functionality.

Emerald™ Electric Wireline Unit

Automation for Modern Wireline Operations

Integrating advanced digital and automation technology to deliver unmatched efficiency, safety, and precision. Equipped with proprietary MDT™ control systems, it offers seamless “cruise control” for pump-down operations and precision winch control, delivering unmatched efficiency and accuracy.

- Direct Drive Drum: Motor-mounted for enhanced reliability and control.

- Rotating Drum Base: +/- 10 degrees for quick and easy spotting.

- Automated Controls: Adaptive tension control (“Auto Pilot” pump-down) and target speed auto-control.

- Integrated Monitoring: Auto-rate touchscreen pump control and digital head monitoring.

Maximizing the Value of Emerald™ Fleets: Integrated Fuel and Power Management

NexTier’s integrated fuel and power management systems are designed to unlock the full potential of Emerald™ fleets, delivering advanced solutions for natural gas fueling, field gas processing, and on-site power management.

- CNG Solutions: Maximizes wellsite efficiency with high-capacity decompression units, advanced trailers, and seamless 24/7 connectivity, reducing operational downtime and costs.

- Field Gas Solutions: Optimizes fueling performance and lowers operational costs with innovative field gas processing technologies, including dynamic BTU control and enhanced safety systems.

- Power Management: Enhances operational safety and uptime with centralized monitoring, remote activation capabilities, and seamless integration across power equipment.

NexHub™ Digital Center Support