- Operations

-

-

- Hydraulic FracturingTailored frac solutions to balance your pricing, operational and environmental goals.

- Wireline OperationsProven history of delivering outstanding results in challenging well conditions.

- Natural Gas FuelingReduce your overall fuel costs with CNG and field gas.

- Oilfield LogisticsNext-generation transport services to keep your wellsite running like a well-oiled machine.

-

mm operations -

Integrated completions expertise: NexTier delivers.

Solid alignment across our operations = stronger alignment with your goals.

-

-

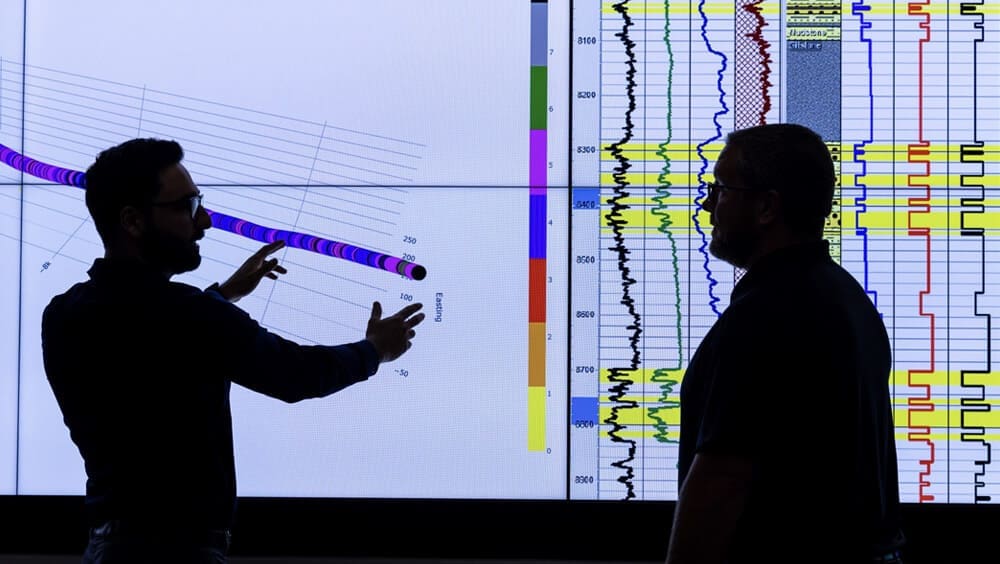

- Digital Solutions

-

-

mm digital -

Next-gen optimization. Superior performance in every well.

The future is now: Digital innovation to elevate your ROI.

-

- Engineering Technology

-

-

- IntelliStim℠ Frac Optimization SystemMonitor every aspect of your frac operations in real time.

- LateralScience℠ Engineered CompletionsThe low-investment, high-ROI solution to optimize horizontal completions.

- Hydraulic Fracturing TechnologiesEngineered fracturing fluids and high-performance chemistries.

- Integrated Engineering TechnologiesImprove reservoir understanding. Eliminate reservoir underperformance.

-

mm engineering -

Tap in to the well’s full downhole potential.

Don’t leave recoverable production and profitability behind.

-

-

- About

-

-

mm about -

The evolving oil field demands evolving service providers.

Sustainable practices and equipment that supports our customers’ ESG goals while accelerating production in the most demanding US land basins.

-

- Careers